Total Water Management Services

Recycling, Oil Recovery, Reporting, Truck Push Services, Chemicals & ClO2 Treatment

Total Water Management Services

Recycling, Oil Recovery, Reporting, Truck Push Services, Chemicals & ClO2 Treatment

We Challenge The Status Quo Of The Oil And Gas Industry.

We identify solutions for supply chain cost control, environmental impact reduction, data reporting and logistics for water management services.

Our solutions include, Water Recycling, Oil Recovery, Reporting, Water Testing, Chemicals, and Mixing Plant Services and Sales.

The new dsu 2.0 unit

Our newest units are all electric, class 1 / Div 1 certified. They include a fully automated self-cleaning filtration system to 20 micron absolute. A comprehensive data acquisition system for tracking viscosvity, flow-rate, pH, salinity, temperature, and conductivity providing 24 hour and End of Job reporting.

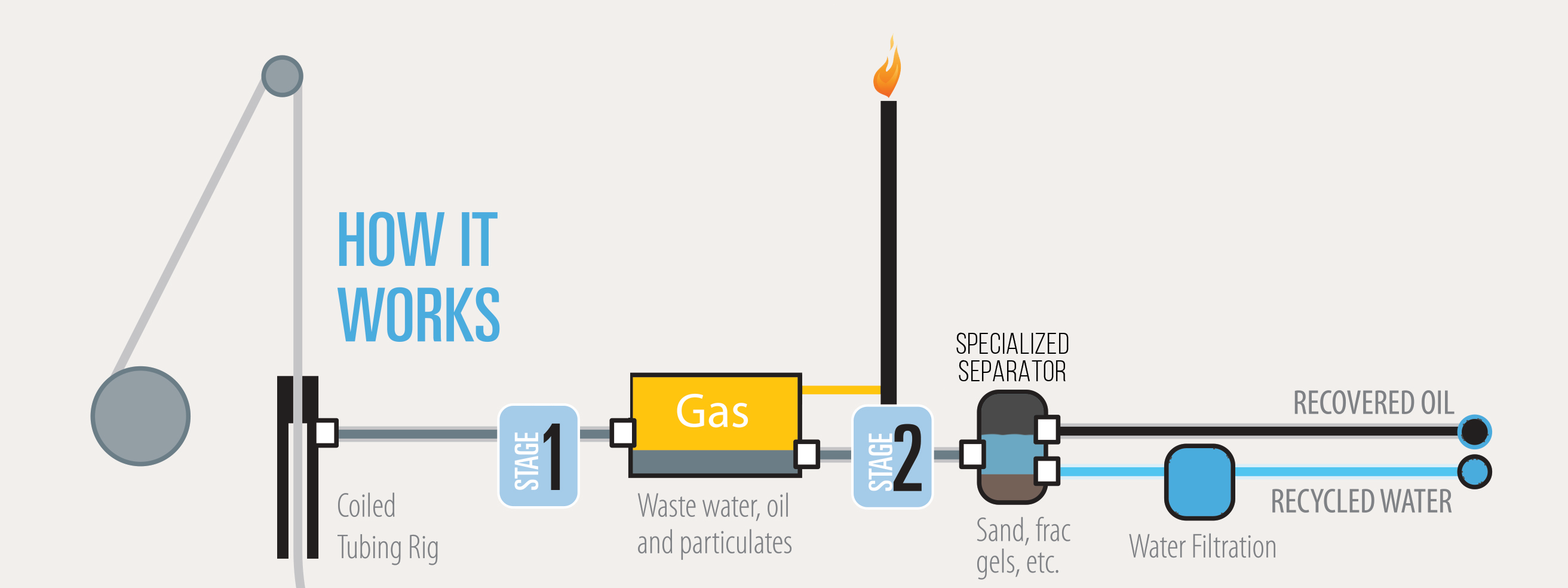

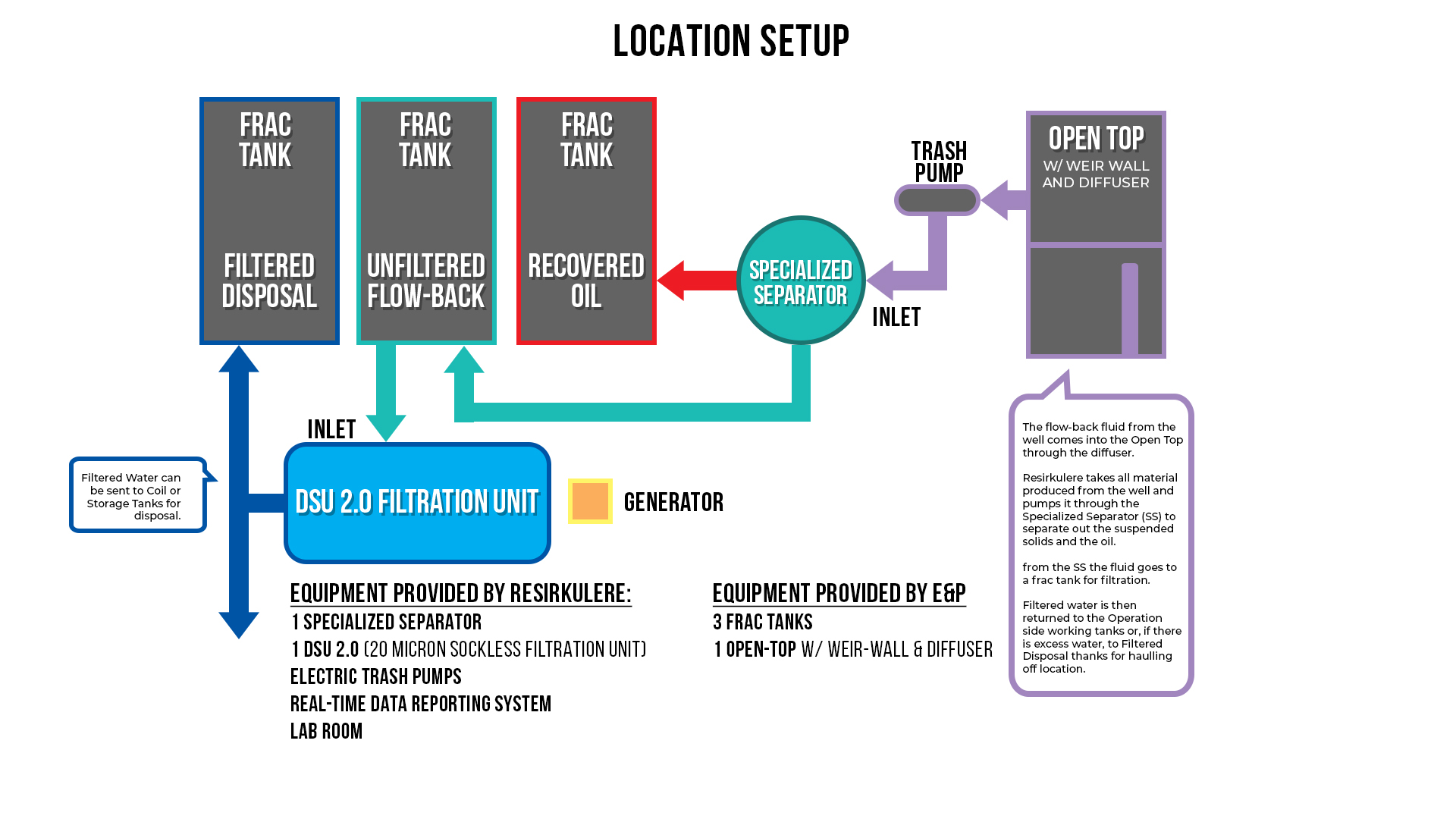

Specialized Separator

Specialized Separator Features:

- 99% reduction in Total Suspended Solids (TSS)

- Fully portable and small footprint

- Breaks emulsions

- Effectively separates and recovers oil from flow back fluid that is missed by the pressure vessel. This is often a significant amount.

Our Specialized Separator effectively separates and

recovers oil from flow back fluid that is missed by the pressure vessel.

By passing the flow back fluid through our SS before filtration, Resirkulere is able to achieve what filtration alone cannot: processing flow back fluid on location, in real time, at high volume in a closed loop.

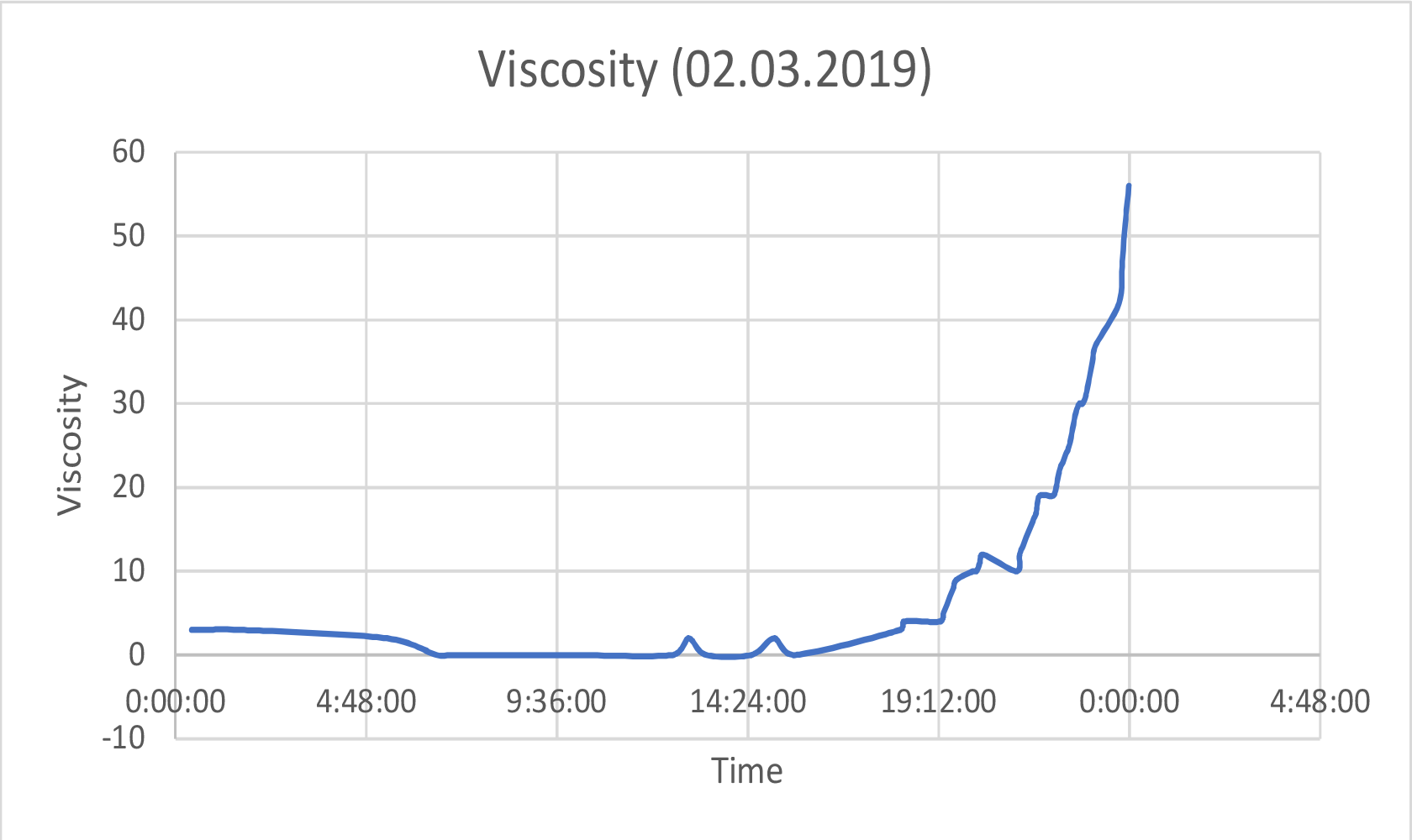

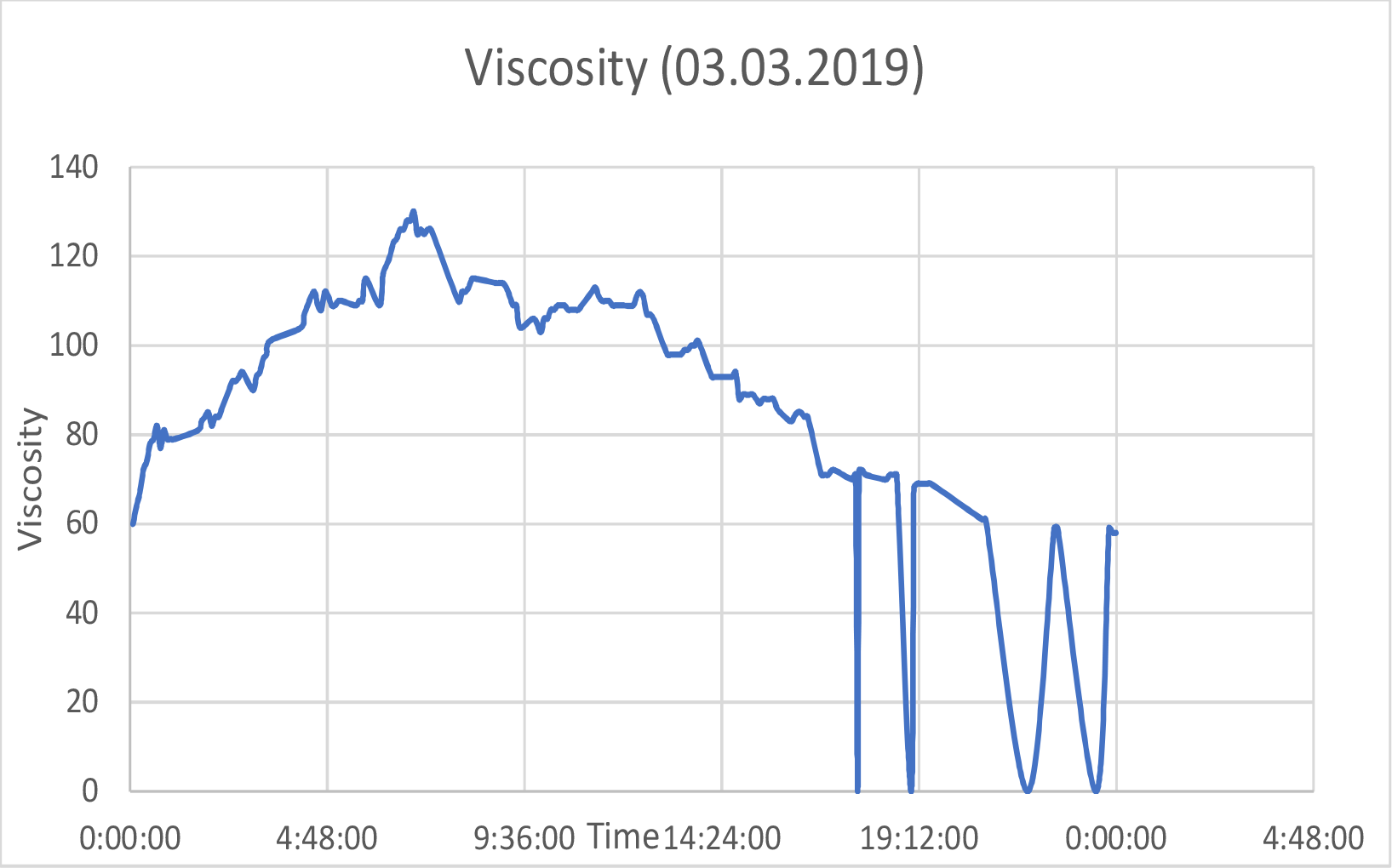

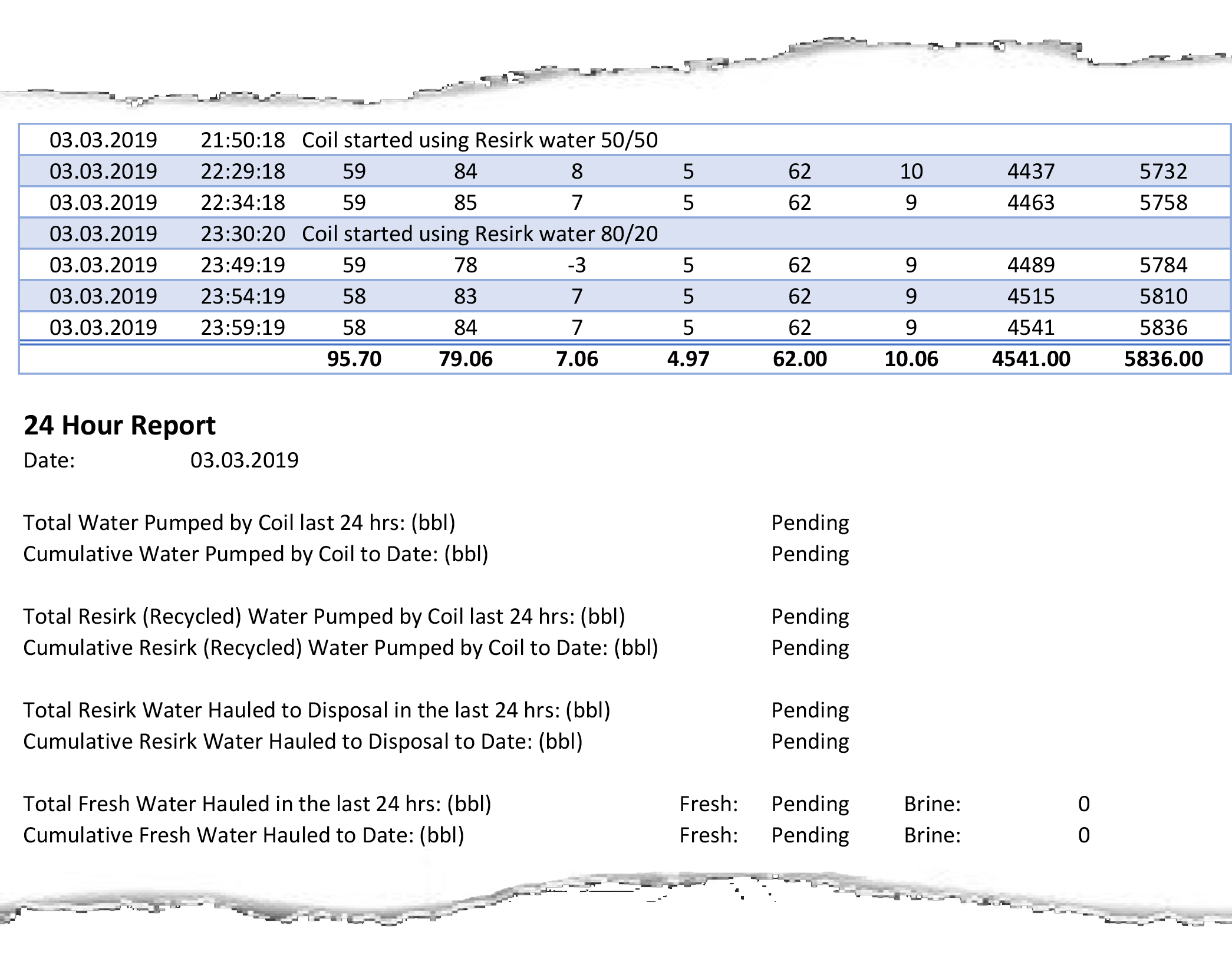

Real-Time Reporting

We offer comprehensive data acquisition system for tracking viscosvity, flow-rate, pH, salinity, temperature, and conductivity providing 24 hour and End of Job reporting.

Chemicals

Resirkulere has partnered with several major chemical providers as a wholesale distributor. Whether it’s frac chemicals, production chemicals, or any other application, if you don’t see it on our list we can get it for you, just let us know.

Friction Reducers

At Resirkulere we have a vast line of Friction Reducers and are ready for any application in the field. Whether it’s fresh water or high brine application we have the solution for you. Our high visc FR also gives our customers to viscosify the entire system and greatly pull reduce the need for gel sweeps.

Pipe Lubricants

Torque and Drag won’t be an issue with our Torque Free lubricants. With products ranging from our base Torque Free which covers most application, Torque Free X which has a liquid graphite base mixture we will keep the pipe slick and moving throughout the job.

Polymers

Whether your application calls for HEC based or an Xanthum based gel you will find our products here at Resirkulere provide optimum yield time for quick viscosity. The big winner for our gels is the return viscosity and amount of product we bring back to surface.

ClO2 Services

FRAC

ClO2 can be used in FRAC operations to disinfect the frac fluid before being sent downhole. Such treatment mitigates issues with bacteria, iron sulfide, and H2S from the beginning. This treatment ensures better quality oil production and higher return on investment due to lower equipment maintenance costs.

Pits & Tanks

Sterilize and disinfect water in pits or tanks. ClO2 can be used on produced water as well to clean it so it can be reused many times before needing to be replenished.

SWD

ClO2 will help break up any oil/water emulsions in the holding tanks of SWD systems for better separation. If bacteria and iron sulfide are causing well injection pressures to rise, ClO2 can be used to destroy the bacteria and break up the iron sulfide, thereby lowering well injection pressure. This can be done on a treatment schedule or at each truck offloading. Keeps storage tanks clean in the process.

Downhole (Production)

ClO2 can be used on wells currently in production to remediate problems with bacteria, iron sulfide, H2S and scaling. ClO2 treatment will help maintain the casing, tubing, and wellhead. It will help produce better quality oil as the ClO2 removes existing bacteria from the formation.

Advantages

- Selective oxidant with low corrosion profile

- Does not form colloidal sulfur

Effective biocide over broad set of conditions - Kills all bacteria, removes biomass

- Improves oil recovery

- Improves SWD skim oil quality by removing sulfides

- Controls H2S in tank headspace

- Improves well production / injection rates by removing well bore contamination

- Reduces corrosion by removing H2S I FeS

Meet our Team

Corey Stormoen

CEO

Marshall Huwe

COO

marshall.huwe@resirkulere.com

Direct: 701-353-2274

Cell: 512-630-4724

Dawn Volk

HSE

John Woods

VP Operations

Reach Us

We are always here to answer any questions you may have.

(701) 484-0070 Main

info@resirkulere.com